FrameworX 10.1

The Modern SCADA Platform. Built on .NET. Unified by Design.

FrameworX 10.1 delivers robust real-time operations, native UNS architecture, and AI-ready foundation in one complete industrial platform.

Aim high, start simple, scale without limits.

Operating in Critical Infrastructure

30+ Years Industrial DNA | 5,000+ Global Deployments

Tatsoft powers mission-critical operations worldwide. Our core team developed platforms embedded in leading automation products, bringing proven reliability to every deployment.

- Oil & Gas: 800 wells modernized, 75-80% operational cost reduction

- Steel: Largest flat steel producer in South America, 100k tags, 50% reduction in development time

- Transportation: 60% reduction in field personnel for rail signal testing

- FDA-Regulated: Pharmaceutical and food production facilities in EMEA

Why FrameworX Delivers More

Modern Foundation

Built on 100% managed .NET code with zero legacy constraints. Green-field design delivers proven performance: 1M+ tags/second processing, 1000+ concurrent clients, <30 second startup.

Unified by Design

Single designer environment for all modules. WebAssembly deployment enables true portability – build once, run on desktop, web, and mobile without plugins or rewrites. Git-based DevOps with JSON export included.

Complete from Day One

Every module included: Devices, Alarms, Historian, Reports, Scripts, Datasets, Security, DevOps tools. No modules to buy, no feature restrictions, no integration headaches.

Operations + UNS + AI-Ready in One Platform

FrameworX 10.1 unifies your entire operation: millisecond SCADA performance for real-time control, native Unified Namespace for data convergence, and AI-ready architecture to scale into the future.

Operations

Built on .NET.

Industrial-grade SCADA

Millisecond performance

Build once, deploy anywhere (Windows, Linux, Docker).

Unified Namespace

Built-in MQTT broker & client (with SparkplugB)

Local UNS definition

Dynamic Global UNS linking

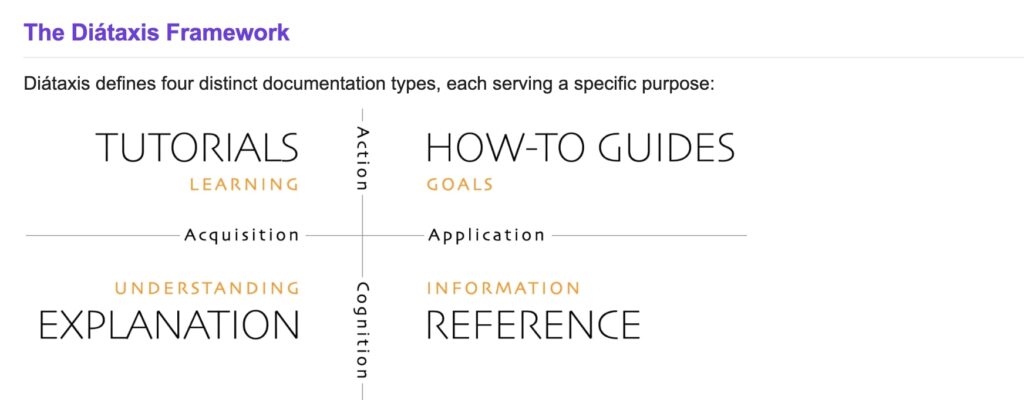

AI-Ready

ML Integration

MCP tools

AI documentation assistant

100+ connectors built-in for true connectivity

Applications We Make Possible

Everything included, nothing extra to buy. A complete toolbox to create SCADA, HMI, IIoT, MES, dashboards, and more — all in one platform.

Enterprise

Connect your plants to your ERP system

Mobile & HTML5

One graphic environment – desktop to web

One Platform, Zero Add-Ons

Our all-inclusive philosophy means predictable costs and immediate capability.

All features included. No modules to buy.

Predictable costs, no hidden fees.

Growth without penalties—unlimited tags and clients.

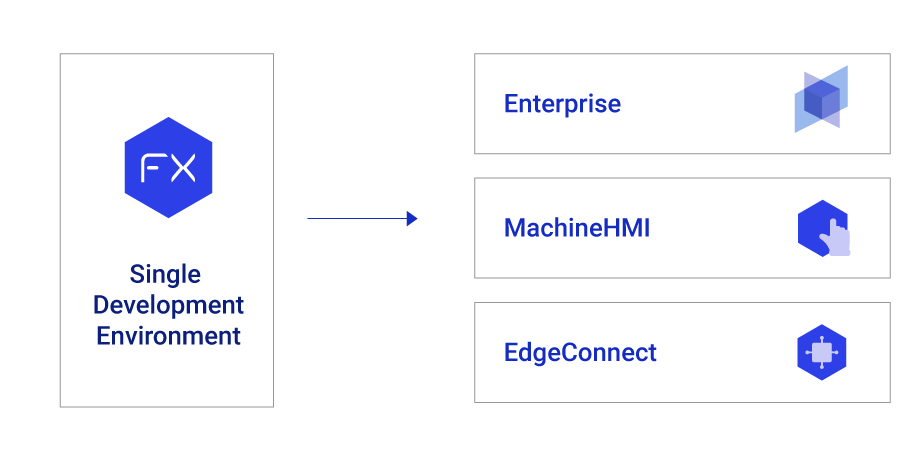

One Platform. Edge to Enterprise.

Three editions, one foundation. Start small or go big — every step builds on the same complete platform, so your investment is always preserved.

- Enterprise: Unlimited SCADA + IIoT platform for plant-wide and multi-site scale — dashboards, analytics, and AI-ready.

- MachineHMI: Full-featured HMI/SCADA for standalone machines — unlimited tags, alarms, historian, and local control.

- EdgeConnect: Industrial edge platform with local processing, SQL, scripting, and 100+ built-in connectors.

The Responsive Alternative

Direct engineer-to-engineer support and an SI program designed for faster deployment and higher margins. Join a focused community where your voice shapes the product.

It’s not uncommon to hear, “This is like magic,” during Tatsoft training sessions when customers are upgrading from legacy solutions. Tasks such as design or troubleshooting can be completed in just one-tenth of the time with Tatsoft compared to traditional legacy systems.

- Control System Technologies

One of the main reasons we decided to work with Tatsoft is they have decades of experience in developing software products and understand the need to have a flexible, reliable platform on which to build applications that will last a long time.

- Renifer Systems

I can’t tell you how many people have come through this building. International groups are very interested. We like showing it off. The system is a big change from what we had; everybody appreciates it.

- Cargill Feed Safety Research Center

The other packages we looked at were either extremely long in the tooth, could only communicate with a single PLC, or were lacking in data collection capabilities (…) FrameworX also provides the tools for us to make complex animations that were essential for us to separate ourselves from the competition.

- Rite Irrigation LLC

Other key factors leading to our decision to use FrameworX were the wide range of options for displaying graphics, built-in .NET scripting for special requirements, communication flexibility, and competitive pricing.